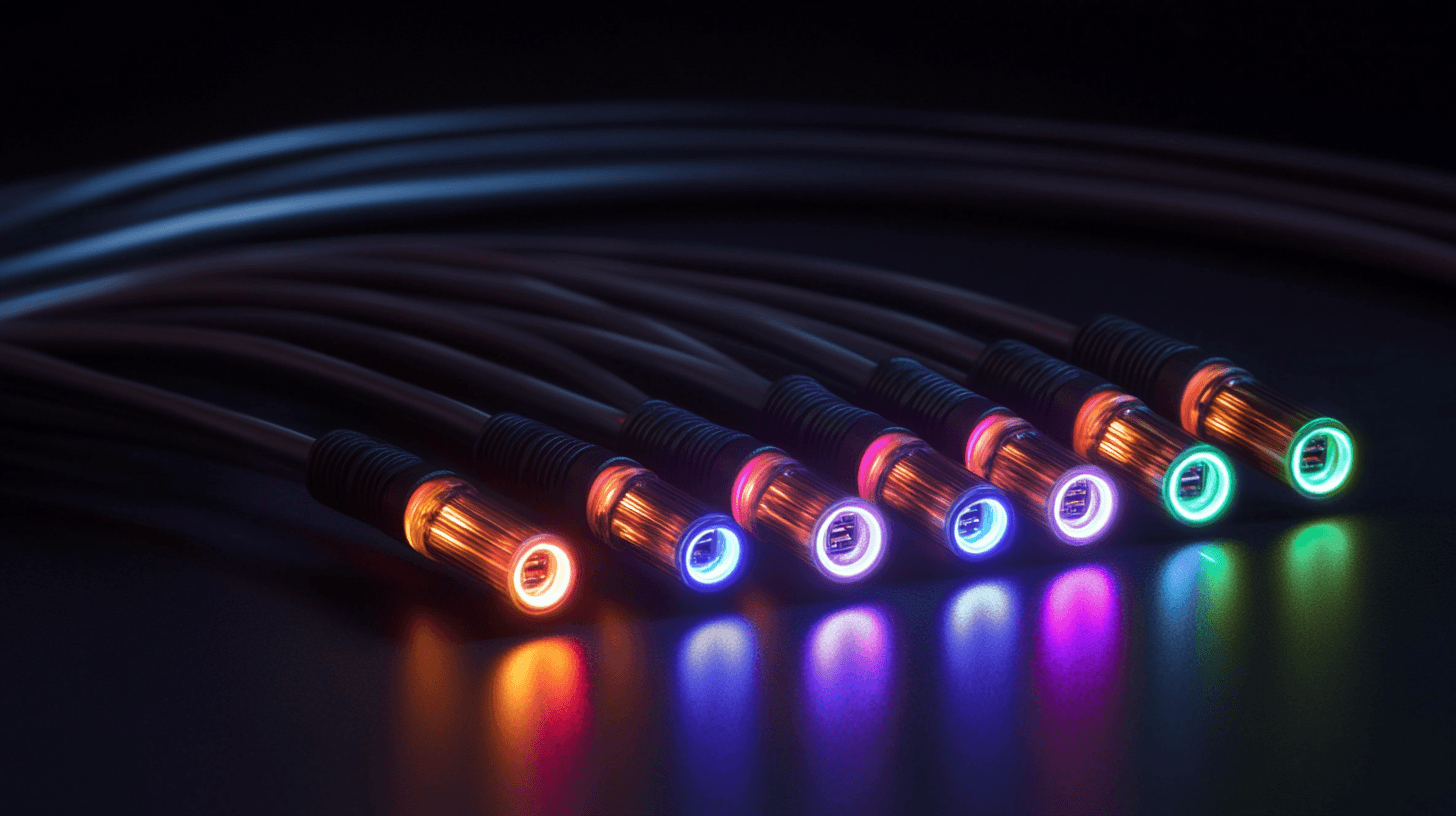

Custom Fiber Optic Assemblies: Tailored Solutions for Advanced Applications

In the rapidly evolving world of fiber optics, off-the-shelf solutions often fall short of meeting the complex demands of cutting-edge applications. This is where custom fiber optic assemblies come into play, offering tailored solutions that push the boundaries of what's possible with light transmission. At Fiberoptic Systems Inc. (FSI), we've been at the forefront of custom fiber optic assembly manufacturing since 1982, delivering high-quality, application-specific solutions across various industries.

What are Custom Fiber Optic Assemblies?

Custom fiber optic assemblies are precisely engineered fiber optic components designed to meet specific application requirements that cannot be satisfied by standard, off-the-shelf products. These assemblies can range from simple single-channel cables to complex multi-furcated bundles with hundreds of fibers, each tailored to perform optimally in its intended environment and use case.

The beauty of custom assemblies lies in their versatility. They can be designed to withstand harsh environments, deliver precise light transmission for medical procedures, or facilitate high-speed data transfer in unique industrial settings. By tailoring every aspect of the assembly - from fiber type and diameter to connector choice and protective jacketing - we can create solutions that perfectly match the specific needs of each application.

FSI's Expertise in Custom Assemblies

At Fiberoptic Systems Inc., we bring over four decades of experience to every custom assembly we create. Our team of expert engineers and technicians combines deep knowledge of fiber optic principles with state-of-the-art manufacturing capabilities to deliver solutions that exceed expectations.

What sets FSI apart in the realm of custom fiber optic assemblies?

Comprehensive In-House Capabilities: From design and prototyping to full-scale production, we handle every aspect of the assembly process in-house. This allows us to maintain strict quality control and offer unparalleled flexibility in design and manufacturing.

Cutting-Edge Technology: Our advanced fiber draw tower allows us to produce over 1,000 miles of fiber per shift, ensuring we have the right fiber for any application.

Industry-Spanning Experience: We've developed custom solutions for a wide range of industries, including medical, industrial, spectrometry, and test & measurement. This diverse experience informs our innovative approach to new challenges.

Commitment to Quality: Our rigorous quality control processes ensure that every assembly we produce meets the highest standards of performance and reliability.

Collaborative Approach: We work closely with our clients, leveraging our expertise to turn their unique requirements into reality.

Customization Variables: Tailoring Every Detail

The power of custom fiber optic assemblies lies in the ability to fine-tune every aspect of their design. At FSI, we consider a wide range of variables to create the perfect assembly for each application:

Fiber Diameter: From ultra-thin fibers for minimally invasive medical devices to larger diameters for high-power industrial applications.

Fiber Type: Single-mode, multi-mode, or specialty fibers chosen based on wavelength, transmission distance, and other factors.

Randomization and Mapping: Custom arrangements of fibers within a bundle to achieve specific light distribution or signal processing goals.

Wavelength Range: Optimized for specific spectral ranges, from UV to near-infrared.

Length: Precisely cut to meet exact distance requirements.

Sleeving Material: Chosen to provide the right balance of flexibility, durability, and environmental protection.

Connectors: A wide range of standard and custom connectors to ensure compatibility and optimal performance.

By carefully considering each of these variables, we can create assemblies that not only meet but exceed the performance requirements of even the most demanding applications.

Industry-Specific Applications

Our custom fiber optic assemblies find applications across a wide range of industries, each with its unique set of challenges and requirements. Let's explore some key areas where FSI's custom solutions are making a difference:

Medical

In the medical field, precision and reliability are paramount. Our custom assemblies are used in various medical devices and procedures, including:

µFiberScope: Ultra-thin fiber bundles for minimally invasive diagnostics and surgeries.

Oximetry: Specialized assemblies for accurate blood oxygen measurement.

Surgical Headsets: Delivering bright, focused illumination for surgeons.

Tissue Analysis: Custom probes for spectroscopic tissue examination.

Learn more about our medical fiber optic solutions

Industrial

Industrial applications often require robust assemblies that can withstand harsh environments while delivering high performance. Our custom solutions in this sector include:

Ringlights: Providing uniform illumination for machine vision and inspection systems.

Multi-Leg Lightguides: Distributing light to multiple points in complex machinery.

Automotive: Custom assemblies for in-vehicle lighting and data transmission.

Semiconductor Manufacturing: High-precision assemblies for wafer inspection and lithography.

Spectrometry

Spectrometry demands high-precision light transmission and collection. Our custom assemblies for this field include:

Spectrometer Bundles: Precisely arranged fiber bundles for accurate spectral analysis.

Optical Slits: Custom-designed slits for optimal light input into spectrometers.

Reflection Probes: Specialized probes for non-destructive material analysis.

Test and Measurement

In the world of test and measurement, our custom assemblies provide the accuracy and reliability needed for critical data collection:

Tooling and Inspection: Custom probes and assemblies for quality control in manufacturing.

Environmental Monitoring: Specialized sensors for detecting pollutants or measuring atmospheric conditions.

Telecommunications Testing: High-performance assemblies for testing fiber optic networks.

FSI's Unique Capabilities

What truly sets FSI apart is our comprehensive range of in-house capabilities, allowing us to tackle even the most complex custom assembly challenges:

Multi-Leg Lightguides: Creating complex branched assemblies for distributed light delivery.

Faceplates: Custom-designed for specific imaging or light shaping requirements.

LED Integration: Incorporating LED sources directly into custom assemblies.

Injection Molding: Creating custom housings and components for perfect integration.

Imaging Bundles: Fabricating coherent fiber bundles for high-resolution image transmission.

Vacuum Feedthrough: Designing assemblies that maintain integrity in vacuum environments.

Custom Connectors: Developing unique connector solutions for special applications.

These capabilities, combined with our extensive experience, allow us to create truly unique solutions that push the boundaries of what's possible with fiber optics.

The Custom Assembly Process: From Concept to Reality

Creating a custom fiber optic assembly is a collaborative process that leverages FSI's expertise to bring our clients' visions to life. Here's an overview of our approach:

Requirement Analysis: We work closely with clients to understand their specific needs, performance requirements, and environmental considerations.

Design and Prototyping: Our engineers develop detailed designs and create prototypes for testing and refinement.

Material Selection: We choose the optimal fibers, coatings, and components based on the application requirements.

Manufacturing: Leveraging our state-of-the-art facilities, we produce the custom assemblies with precision and care.

Quality Control: Rigorous testing ensures each assembly meets our high standards and client specifications.

Delivery and Support: We provide comprehensive documentation and ongoing support to ensure the success of each custom solution.

This process ensures that every custom assembly we produce is not just a product, but a tailored solution designed to excel in its intended application.

Conclusion: Empowering Innovation with Custom Fiber Optic Assemblies

Custom fiber optic assemblies represent the cutting edge of fiber optic technology, offering unparalleled flexibility and performance for advanced applications. At Fiberoptic Systems Inc., we're proud to be leaders in this field, combining decades of experience with state-of-the-art capabilities to create solutions that drive innovation across industries.

Whether you're developing next-generation medical devices, optimizing industrial processes, or pushing the boundaries of scientific research, FSI has the expertise and technology to bring your vision to life. Our custom fiber optic assemblies are more than just components – they're the key to unlocking new possibilities in light transmission and data communication.

Ready to explore how custom fiber optic assemblies can transform your application? Contact our team of experts today to discuss your unique requirements and discover the FSI difference.

Let's illuminate the future, one custom assembly at a time.

Frequently Asked Questions about Custom Fiber Optic Assemblies

Q1: What are the advantages of custom fiber optic assemblies over off-the-shelf solutions?

Custom fiber optic assemblies offer several advantages:

Tailored to specific application requirements

Optimized performance for unique environments

Ability to integrate multiple functions in a single assembly

Potential for space and cost savings in complex systems

Customized for specific wavelengths, power levels, or signal integrity needs

Q2: How long does it typically take to develop a custom fiber optic assembly?

The development time can vary depending on the complexity of the project. Simple customizations might take a few weeks, while more complex designs could take several months. At FSI, we work closely with our clients to establish realistic timelines based on their specific needs and project requirements.

Q3: Are custom fiber optic assemblies more expensive than standard products?

While the initial cost of a custom assembly may be higher than an off-the-shelf product, it often provides better value in the long run. Custom assemblies can offer:

Improved performance in your specific application

Longer lifespan due to optimized design

Reduced system complexity by combining multiple functions

Potential cost savings in installation and maintenance

Q4: Can FSI help with the design process if I'm not sure exactly what I need?

Absolutely! Our team of experienced engineers is here to guide you through the entire process. We can help you analyze your requirements, suggest optimal solutions, and collaborate on the design to ensure the final product meets your needs perfectly.

Q5: What industries typically require custom fiber optic assemblies?

Custom fiber optic assemblies are used across a wide range of industries, including:

Medical and life sciences

Aerospace and defense

Industrial automation and robotics

Telecommunications

Oil and gas

Research and development

Spectroscopy and analytical instruments

Q6: How do you ensure the quality and reliability of custom assemblies?

At FSI, we maintain strict quality control throughout the entire process:

We use only high-quality materials from trusted suppliers

Our in-house manufacturing allows for tight control over every step

We perform rigorous testing on all assemblies before delivery

We offer comprehensive documentation and support

Our products are backed by warranties and our commitment to customer satisfaction

Q7: Can you create custom connectors or terminations?

Yes, we have extensive capabilities in creating custom connectors and terminations. Whether you need a unique connector design, a special polish on the fiber end, or a custom housing, our team can develop a solution that meets your specific requirements.

Q8: How do I get started with a custom fiber optic assembly project?

To begin your custom fiber optic assembly project with FSI:

Contact our sales team through our website or by phone

Describe your application and requirements

Our engineers will schedule a consultation to discuss your needs in detail

We'll provide a proposal outlining the design, timeline, and costs

Upon approval, we'll begin the design and prototyping process

We're here to support you every step of the way, ensuring that the final product exceeds your expectations.

Key Points: Custom Fiber Optic Assemblies at FSI

Why Choose Custom Fiber Optic Assemblies?

Tailored Solutions: Designed to meet specific application requirements that off-the-shelf products can't satisfy.

Optimized Performance: Engineered for optimal performance in unique environments and use cases.

Versatility: Suitable for a wide range of industries including medical, industrial, and scientific research.

Innovative Designs: Push the boundaries of what's possible with fiber optic technology.

FSI's Custom Assembly Capabilities

Comprehensive Customization: From fiber type and diameter to connectors and protective jacketing.

In-House Manufacturing: Complete control over the production process, ensuring high quality and flexibility.

Advanced Technology: State-of-the-art fiber draw tower and manufacturing facilities.

Experienced Team: Over 40 years of expertise in fiber optic technology.

Quality Assurance: Rigorous testing and quality control processes.

Industries We Serve

Medical and Life Sciences

Industrial Automation

Aerospace and Defense

Spectroscopy and Analytical Instruments

Telecommunications

Research and Development

Our Process

Requirement Analysis

Design and Prototyping

Material Selection

Manufacturing

Quality Control

Delivery and Support

Choose FSI for custom fiber optic assemblies that meet your exact specifications and drive innovation in your field. Contact us today to start your custom project.

Standard vs. Custom Fiber Optic Assemblies Comparison

Custom fiber optic assemblies from FSI offer unparalleled flexibility and performance optimization for specialized applications across various industries. While they may have a higher initial cost and longer lead time, the benefits in terms of performance, integration, and long-term value often outweigh these factors for complex or mission-critical systems.