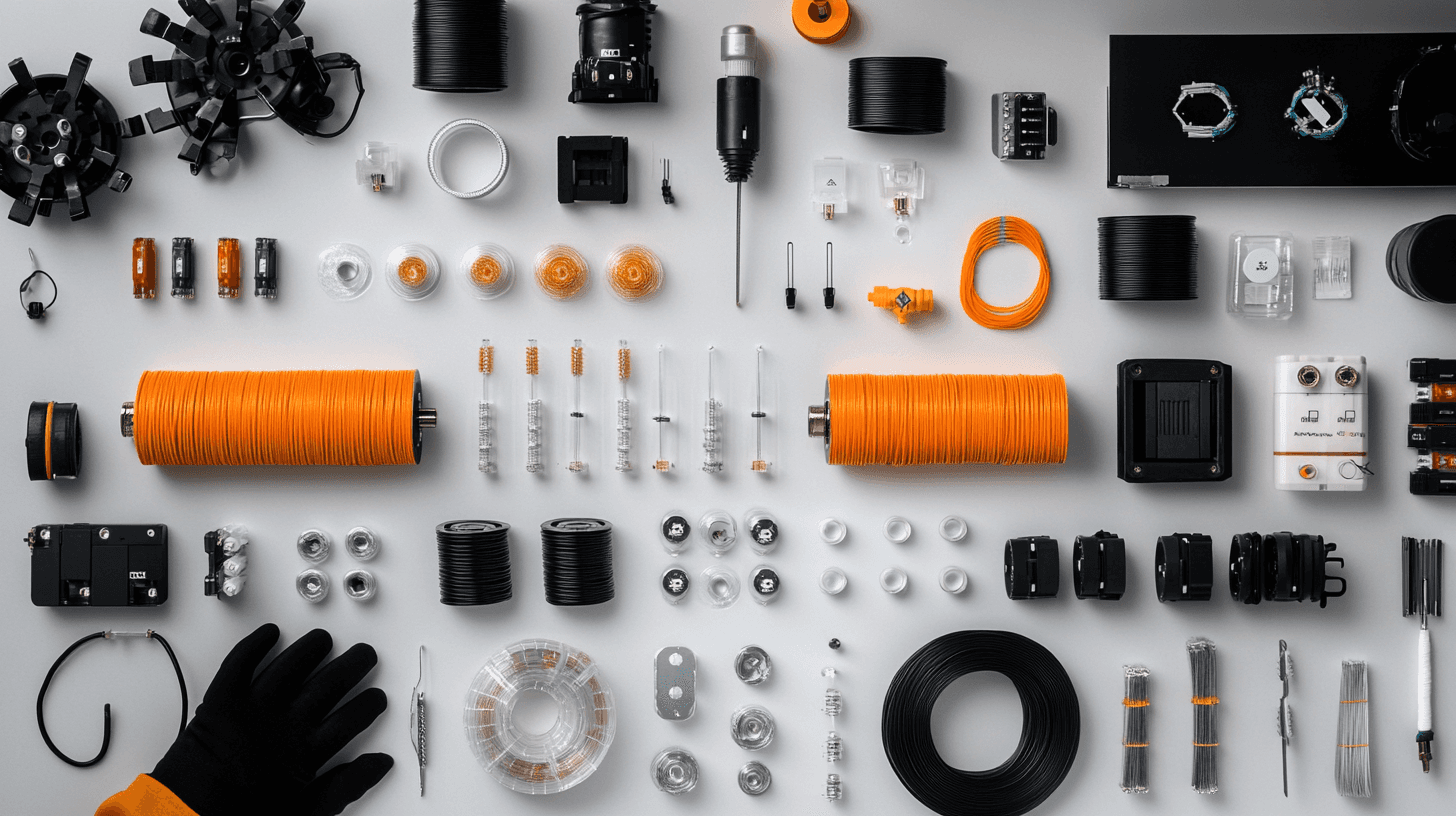

A custom fibre optic assembly is not just a cable; it’s a precisely engineered system designed to meet specific performance, environmental, mechanical, and optical requirements. Every element—starting from the type of fibre and connector to the material of the jacket—contributes to the overall functionality and longevity of the cable. Making informed decisions at each stage ensures that the final product is well-suited to its intended application, whether that’s a state-of-the-art medical endoscope, a high-performance aerospace sensor link, a rugged industrial robot, or a telecommunications backbone.

FSI’s custom configuration interface offers a guided approach to designing such assemblies. By providing options for connector types, fibre materials, numerical aperture, core diameter, and sheathing/jacket materials, the platform helps you build a solution step-by-step. Let’s break down each major selection category.

Connector Types

Why Connectors Matter:

Connectors are the critical end-points that interface your fibre cable with other system components—transmitters, receivers, sensors, diagnostic equipment, or patch panels. A good connector ensures minimal insertion loss, stable alignment of the fibre core, secure mating, and long-term reliability under varying environmental conditions. Different connectors also have different ferrule materials, polishing standards, and industry acceptance.

Common Connector Types:

SMA:

Overview: SMA connectors (SubMiniature A) are often used in more industrial or niche applications. They have a threaded coupling mechanism that ensures a secure fit.

Advantages: Rugged, reliable in environments with vibration; commonly used with larger core fibres (e.g., some multimode step-index fibres) and less sensitive systems.

Considerations: Not as low-loss or as high-precision as modern telecom connectors. More mechanical complexity and a slightly more cumbersome mating process.

FC/PC:

Overview: FC (Ferrule Connector) with a Physical Contact (PC) polish is a long-standing standard in telecom and lab environments. It uses a threaded coupling nut for mechanical stability.

Advantages: Stable and repeatable connections with low back reflection and good insertion loss characteristics. The PC polish ensures a good physical contact between fibre end-faces.

Considerations: Threaded connection is robust but may be slower to mate/unmate compared to push-pull connectors (like LC or SC).

FC/APC:

Overview: Similar to FC/PC, but with an Angled Physical Contact (APC) polish at an 8° angle.

Advantages: Significantly reduced back reflection (< -60 dB typically), making these ideal for high-precision measurements, test systems, or laser delivery applications where return loss is critical.

Considerations: APC connectors must mate with other APC connectors. The angle polishing introduces complexity during termination, but it’s worth it for sensitive systems.

Custom:

Overview: When your application requires a connector not listed—maybe a proprietary medical device interface or a specialized aerospace-grade fitting—this is the option.

Advantages: Absolute flexibility. You can specify geometry, material, end-face preparation, and any industry-specific standard.

Considerations: May require engineering consultation, custom tooling, or non-standard polishing processes. Longer lead times and higher costs are expected.

Unsure:

When Chosen: If you’re not certain which connector suits your project, choosing “Unsure” signals you may need additional support.

Advantages: FSI experts can guide you in selecting the right connector after discussing your system’s requirements.

Considerations: Expect back-and-forth consultation.

Fibre Type Selection

Why Fibre Choice is Important:

The fibre’s core and cladding composition determine attenuation, bandwidth, operating wavelength, mechanical robustness, and compatibility with light sources. Different materials also influence cost, environmental resistance, and the ease of integration with connectors and optical components.

Available Fibre Types:

Borosilicate Fiber:

Overview: Borosilicate glass fibres are robust and can withstand harsh conditions, temperature variations, and certain radiation environments better than conventional telecom silica fibres.

Applications: Often used in industrial sensing, illumination, or medical devices where mechanical strength and temperature tolerance are key.

Considerations: Might have slightly higher attenuation than pure fused silica depending on wavelength. Great for illumination bundles or imaging fibres.

Quartz (Fused Silica):

Overview: Typically, when the industry says “quartz” fibre, they mean high-purity fused silica core and cladding. This is the gold standard for telecom and high-performance applications.

Advantages: Ultra-low attenuation, broad wavelength transmission (UV to IR), excellent for data communications, spectroscopy, and high-power laser delivery when properly coated.

Considerations: Generally more expensive but unbeatable performance. Widely compatible with standard telecom connectors and known refractive indices.

Plastic Optic Fiber (POF):

Overview: POF uses a polymer core, typically PMMA, and offers large core diameters (e.g., 0.5-1 mm), easy handling, and simple termination.

Advantages: Very cost-effective, flexible, lightweight, easy to terminate. Great for short-distance, consumer-grade or automotive network applications.

Considerations: Higher attenuation than glass, limited bandwidth and distance, not suitable for harsh temperature or high-power laser applications.

Custom (Add Right):

Overview: If your application requires a specialized doped silica fibre, fluoride fibre for mid-IR, or a double-clad fibre for high-power lasers, custom is the route.

Advantages: Tailored optical properties—NA, core diameter, doping profile. Ideal for very niche R&D projects, medical diagnostics, or unique sensing wavelengths.

Considerations: Requires in-depth consultation, potential custom manufacturing runs, and higher costs.

Unsure:

When Chosen: If you don’t know which material is ideal, “Unsure” indicates that you need guidance.

Advantages: Allows FSI engineers to recommend a fibre based on your wavelength, environment, and bandwidth requirements.

Additional Fibre Parameters to Consider:

Core Diameter & Numerical Aperture (NA): Impacts coupling efficiency, acceptance angle of light, and attenuation.

Wavelength Window: Different fibres excel at different wavelengths (e.g., 850 nm, 1310 nm, 1550 nm for telecom silica fibres; visible range for borosilicate, or even UV transmission for certain specialty fibres).

Numerical Aperture (NA) and Core Diameter

Though not shown extensively in the provided snippet, NA and core diameter often appear as configurable fields:

Core Diameter: Larger cores are easier to couple light into (especially from LEDs or incoherent sources) and are common in multimode applications like illumination or short-haul data links. Smaller cores (single-mode fibres) are for long-distance, high-bandwidth communication or precision sensing.

NA: Determines how much light the fibre can gather. A high NA (~0.22) is common in multimode fibres for illumination. For single-mode fibres, NA is lower, but the mode field diameter and wavelength define its single-mode operation.

These parameters must align with your source, detector, and overall system design.

Jacket/Sheathing Types

Why the Jacket Matters:

The jacket is the first line of defence against the environment, mechanical stress, chemical exposure, and more. It affects flexibility, durability, sterilizability (in medical scenarios), and compliance with safety standards (like LSZH for fire hazard areas).

Common Jacket Materials:

PVC (Polyvinyl Chloride):

Characteristics: Widely used, cost-effective, flexible, decent chemical resistance.

Applications: General-purpose indoor installations, instrumentation cables, and moderate environments.

Considerations: In a fire, PVC can produce halogenated smoke. Not always ideal for confined spaces with strict fire codes.

Silicone:

Characteristics: Highly flexible, good thermal stability, biocompatibility for certain medical applications.

Applications: Medical endoscopes, surgical illumination cables, or equipment that requires repeated sterilization.

Considerations: Silicone jackets are softer and might be less abrasion-resistant. They often excel in medical or lab environments where chemical and temperature resistance are important.

Furcation Tubing:

Characteristics: Furcation tubing is used to reinforce bare fibres or fibre bundles, giving each fibre a mini “jacket” that provides mechanical robustness and makes handling easier.

Applications: Perfect for transitioning from a bulk cable to individual connectors or pigtails; also useful in patch panels or test environments.

Considerations: Furcation tubing ensures fibres remain protected when they exit a main cable’s sheath, preventing breakage.

PVC Coated Mono Coil:

Characteristics: A mono coil (metallic or otherwise) coated with PVC offers enhanced mechanical protection and crush resistance while maintaining flexibility.

Applications: Industrial robotics, machinery, or areas with frequent movement and potential cable impacts.

Considerations: Slightly bulkier and heavier, but worth it if mechanical integrity is a priority.

Stainless Steel Interlock:

Characteristics: A stainless steel interlocked armour is like wrapping your fibre in a metallic spine. This offers outstanding mechanical protection, crush resistance, and rodent deterrence.

Applications: Harsh industrial environments, tunnels, mining, or anywhere cables could be physically abused or require robust rodent protection.

Considerations: Less flexible, heavier, and more expensive. Overkill for benign indoor applications, but invaluable in extreme conditions.

Other (Custom/Other):

Overview: If your application needs a unique material—maybe a fluoropolymer for high-temperature aerospace applications, or a bioinert jacket for medical implants—this is the way.

Considerations: Custom materials mean engineering discussions, special testing, and possibly higher costs.

Additional Jacket Considerations:

Flame Retardancy: Some jackets are available in LSZH variants to meet stringent building codes.

UV Resistance: For outdoor installations, ensure the jacket can withstand UV exposure without cracking.

Chemical Resistance: In chemical plants or labs, the jacket should resist solvents, acids, or oils.

Temperature Range: High-temperature coatings might be needed for aerospace or foundry environments.

Application-Focused Configurations

Medical Endoscopy:

Likely fibre: High-NA quartz or borosilicate for illumination.

Jacket: Silicone or biocompatible polymer.

Connector: Possibly custom medical connectors, or SMA if it integrates with standard medical light sources.

Aerospace and Defence:

Fibre: High-grade fused silica with low attenuation at telecom wavelengths.

Jacket: Stainless steel interlock or special fluoropolymers for high-temp and radiation resistance.

Connector: FC/APC or custom aerospace-grade connectors.

Data Centers / Telecom:

Fibre: Single-mode quartz (for long distances) or multimode quartz (for short links).

Jacket: PVC or LSZH (if building codes require).

Connector: FC/PC, LC, SC, or even custom (though standard telecom connectors are common).

Industrial Sensing (Robot arms, Automated Factories):

Fibre: Possibly multimode quartz or borosilicate.

Jacket: PVC coated mono coil or stainless steel interlock for mechanical resilience.

Connector: SMA or FC depending on sensor interfaces.

Handling “Unsure” Selections

If at any stage you’re unsure—about fibre type, connector type, or jacket—the “Unsure” option is a safety net. It prompts engineering consultation. FSI’s experts can help translate your performance needs (bandwidth, wavelength, mechanical stresses) into technical specifications. Be ready to discuss:

Operating environment (temperature, humidity, presence of chemicals)

Required cable length and bend radius constraints

The wavelengths and light sources in use

Regulatory or safety standards applicable to your industry

This collaborative approach ensures you end up with the right solution rather than a guess.

Beyond the Basics

Additional Customization Options (Not shown in the snippet but commonly available):

Buffering and Strength Members: Kevlar or aramid yarn might be included for tensile strength.

Connector Polish Types: PC, UPC, and APC polishes affect back reflection performance.

Wavelength-Specific Coatings: To reduce attenuation at certain wavelengths or increase durability.

Hybrid Assemblies: Combining fibre optics with electrical conductors or incorporating multiple fibre types in a single cable.

Testing and Validation:

Reputable suppliers can perform insertion loss and return loss measurements, environmental stress testing (thermal cycling, vibration tests), and certification to ensure your custom assembly meets the promised specifications.

Conclusion

Choosing a custom fibre optic solution involves a series of critical decisions—each affecting the cable’s performance, durability, and suitability for your application. By understanding the roles of different connectors, fibre materials, and jacketing options, you can narrow down your choices or at least know where expert consultation might be needed.

FSI’s configuration platform makes the selection process more intuitive by presenting you with structured choices. Whether you end up with a simple PVC-jacketed quartz fibre for a clean data center environment or a heavily armoured, stainless steel-sheathed borosilicate bundle for an offshore drilling sensor system, the key is having the knowledge to pick the right components.

In fibre optics, details matter. A carefully chosen connector ensures stable optical alignment and low insertion loss. The right fibre material guarantees efficient light transmission at your target wavelength. The appropriate jacket protects against the world’s harsh realities—be that salt spray, sterilisation procedures, or rambunctious rodents. With these insights, you’re better equipped to design a cable assembly that hits the sweet spot between performance, reliability, and cost-effectiveness.

The result: a custom fibre optic solution that quietly, reliably, and efficiently gets the job done for years to come.